Earlier this week we attended the Dewalt media event where the stars of the show were the new Dewalt XR Compact Drill/Driver DCD790 as well as the single speed XR impact driver DCF886. The compact Drill/Driver is Dewalt’s first brushless drilling product and will be accompanied shortly by the XR compact hammer drill DCD795. The single speed impact will be their second brushless impact to launch and will be the more cost effective counterpart to the three speed brushless XR DCF895 ($259) impact we saw launched last year.

Together the compact drill and single speed impact will be available in the combo kit DCK281D2 launching at $279, while the hammer drill combo DCK286D2 will hit shelves at $299. These are the most popular combo kits and price points that customers demand, which is exactly why Dewalt made these units the priority for their XR brushless platform with additional tools to follow.

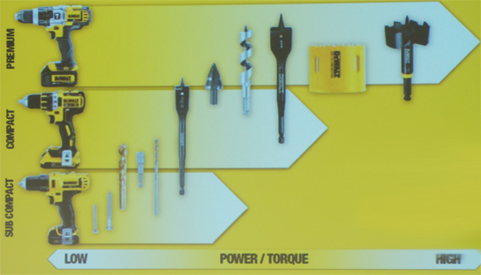

Comparing Compact vs Premium Heavy Duty Drills

One clear distinction that needs to be made (and the folks at Dewalt really emphasized) is that this is a compact brushless drill/driver unit and not their premium heavy duty tool, which will probably come later. One of the challenges we saw when Makita launched their brushless hammer drill LXPH05 ($299, in combo) is they did not make this distinction and folks compared this to the Milwaukee M18 FUEL which is a Heavy Duty brushless drill 2603-22 ($279) and/or hammer drill FUEL 2604-22 ($299) which are both high torque tools. In comparison tests the Makita got smoked, literally, however for low torque applications the Milwaukee tools doesn’t have the same run time, think of it like comparing an SUVs vs sedans. For pulling a boat the SUV will win every time but in fuel efficiency test driving to work, not so much. You just need to know what the range of workloads will you be faced with, just like when picking a vehicle.

It would be our assumption both Makita and Dewalt will have larger brushless drills and hammer drills for high torque applications soon. The largest opportunity for tool sales however is in the mid-size range which addresses many professionals’ needs as well as consumers shopping at the big box stores. Milwaukee’s solution to this need is to shrink the 3 categories above to 2 which they address with their M12 FUEL brushless tools aimed at the professionals and big box customers looking for the mid-low torque tool. With so many different choices now you’ll just have to decide ahead of time what the priorities are, light weight efficient tool or something with the widest range of capabilities? Again for fans of the yellow team we would bet you wont have to wait too long for that premium option in the XR 20V Max line up.

In the video above comparing the different brand’s drills with the Dewalt XR DCD790 (video produced by Dewalt) it is important to remember this is a compact unit ideal for low to mid torque applications such as 3/8” drilling in wood. If Milwaukee had made the same video the test would certainly be with a 1” auger bit or larger and the higher torque Milwaukee would win. We were very disappointed to not see the Makita brushless LXPH05 (technically a hammer drill) in the comparison as it is certainly is the closest true brushless competitor in torque, runtime, price, etc.

Why a Single Speed Impact Driver

Dewalt launched their first brushless about a year ago with a large amount of success. The DCF895 features a 3 speed control, new flush nose bit holder and 3 LED lights. This new DCF886 basically just drops the speed control and the fancy bit holder but keeps the 3 LED light (a great feature) to make a more cost effective product for the combo kits. This is the same approach Makita took with their 1 speed vs 3 speed which we compared in the video below to show the general range of torque on each setting.

We are not fans of the bit holder and we are totally fine dropping that all together. The 3 speed controls we really think is a great option in theory, and as you can see from the video it really works. I wish this would be an option they would keep, again in theory. In practice however with over a year using all of these 3 speed brushless impacts I can’t recall even one time I have ever switched to a lower speed setting for a real world application. For fine, delicate fastening we just don’t automatically go to an impact driver so it hasn’t been an issue and now I probably wouldn’t care either way. The Milwaukee FUEL combo kits, with drill/driver 2791-22CT ($349) & hammer drill 2797-22 ($399) do include their 3 speed impact so if that is a big area of debate in your mind, you might give a point to the red team.

Above is another video produced by the folks at Dewalt comparing the 3 units of course take it for what you will, the Makita uses a 3.0Ah battery (soon to launch 4.0Ah) and the Milwaukee impact is rated for higher torque so we would probably see a higher torque application with different results if the video was produced by Milwaukee. We still think it’s a helpful video in making the decision.

What is the Bottom Line?

What the Dewalt XR brand is all about is Extreme Runtime and to emphasize this at the media event they made the group of 40+ of us compare their existing brushed impact DCF885C2 ($199) & compact drill DCD780 ($215) against the new higher amp batteries and brushless tools (see media event video below). The results were very impressive with almost double the performance compared within their own 20V Max products. Or in other words a product that is very close in price (brushed motors with 1.5Ah batteries) and sitting on store shelves right now will get almost double the production when launched in the coming months with brushless technology and 2.0Ah batteries.

These technology advancements are very impressive and seem to be improving at a much more rapid pace than we’ve ever seen before in power tools. We are very excited to see what the future holds and where the potential of brushless technology will take us with saws, other larger tools and higher capacity batteries. Is there some point in the not to distant future we won’t even need cords on the jobsite?