If you were to ask most people in a plant or on a job site how could manual and electric hoists be improved you first two answers are probably going to be make them safer and able to last longer. While Jet has not always been a product leader, over the past several years they have really begun to lead the way in innovating products for many categories and lifting systems is a shining example of that. The need for better safety in lifting systems have lead to several industry firsts from Jet.

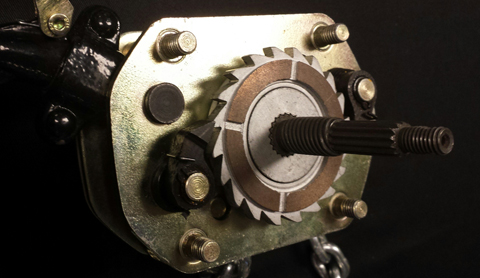

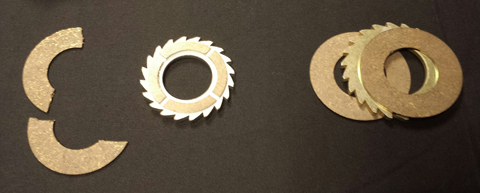

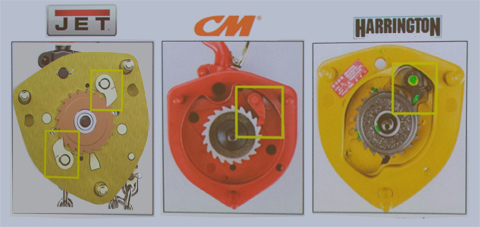

On the Jet manual chain hoists L-100 series several new features really separate the Jet product from the rest of the professional grade competition of Harrington CB, CM (Columbus McKinnon) Cyclone 646 or Coffing LHH. Each of these brands has a mid-range less expensive unit as well as a higher-end offering. Many people, including myself at one point thought the higher priced units (L-100 vs S-90) simply meant better chain (100 grade corrosion resistant zinc coated vs 80 grade black oxide coated) which is true but that’s just the beginning. Another huge differentiator for Jet is the 1 piece fused brake design which is guaranteed for life and as of the publishing of this story they have not had to replace a single one of these breaks due to failure. The more traditional 3 piece break system is what is used by Harrington, CM & Coffing on all their hoists in addition to Jet’s mid-range S90 chain hoists.

The 3 piece break system is still a reliable system but recommends the brake disks to be inspected/replaced every year in “regular” operations. A worn disk is about as easy to snap in your fingers as a thick potato chip and in heavy use these can easily become completely worn out. Just like the brakes in your car when the pads are gone you end up with metal on metal wear which will cause excess friction, heat and eventually failure. Questions you’d want to ask at this point are; dose every hoists get inspected yearly as required? Do you have hoists used in heavy applications that might need inspected more often? Would employees at every level be able to identify and/or report a hoist which may need its breaks replaced?

The Jet L-100 also features a Duel Pawl Weston Brake where the two ratcheting pawls are on opposite sides of the break minimizing stress to either pawl. Again Jet is the only brand to feature this configuration. Both Harrington and CM have a single pawl design and while the Coffing LHH hoist does feature duel pawls they are side by side which would not distribute stress as evenly over the break. These designs are all approved and meet OSHA, ANSI and ASME standards, additional all these brands hoists are factory tested and certified (make sure you keep your certificates) we are certainly are not saying anything to the contrary. These are just a couple examples how Jet is really trying to go beyond the regulations to build a better product (without jacking up the price) to simply keep as many injuries as possible from ever occurring.

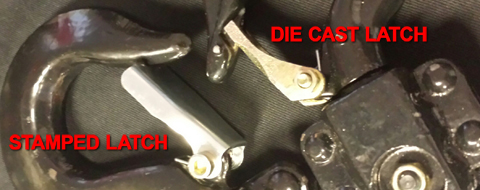

On the Jet JLH Lever Hoists you will see all the same features as the Jet L100 Chain Hoists which include single fused brake with lifetime replacement guarantee (again which has yet to be used) and the duel pawl design. Jet also has a mid-range product JLP-A Lever Hoists which use the similar 3 piece brake system you will find on the competitions top models Harrington LB, CH 653 and Coffing LHH ratchet hoists. On the Jet JLH a few other safety features which separate them from the rest of the pack include die cast latch hooks (stronger than stamped) as well as a corrosion resistant process to the body which will not wear away as easily as the powder coating used by the competition.

Jet didn’t stop with manual hoists and lifts however the improved safety and durability story continues in electric lifting hoists as well with the VOLT variable speed hoists. This is the first and currently only electric hoists to offer a “true” dial variable speed control which can slow down to almost 0 FPM. The competition has offered variable speed before Jet launched the VOLT product about a year ago however these units are really 2 speed and don’t provide the fine adjustments are low speed you would require for precision work.

If you were to look at 2 ton “variable speed” hoists for instance the Jet VOLT goes from 0-24 FPM, the CM (w/VFD) goes 2.5 or 16 FPM and the Harrington (w/VFD) does 2.5 or 14 FPM. These different speeds are controlled by half pressing buttons so by toggling between fully pressed half pressed and off it may feel like you have additional control in the mid range but that’s not really where you need the control. The VOLT product offers the fastest max speed so you can get the load into position in the least amount of time as well as the highest level of control at the very low end where the precision alignment would be needed. By eliminating the need to bump fire or toggling on/off, the VOLT hoist’s motor gets less wear/tear, there is also less jerking and stress on the chain and other components. Of course these factors make the product safer to operate and a relatively inexperienced operator like myself can feel comfortable make precision alignments in a matter of minutes.

Jet has made it a point to continue to innovate by going over and above what is required to meet the specs and look at what is going to be most important to the users. In lifting systems even if the operator is doing everything correctly there are times when outside factors come into play, with hundreds or thousands of pound are in the air an accident can be mean a catastrophe. The folks at Jet have really impressed us with their attention to detail in this category. While much of the competition continues to manufacturer the same products they always have the folks at Jet continue to innovate and ask can they add a feature or provide some redundancy which will make the product safer? From what we’ve seen it would be pretty hard not to consider Jet one of the leaders in safety/innovation for the hoists and lifting category.

If you have any questions about any of the Jet, Wilton, Powermatic brand products the experts at Ohio Power Tool 800-242-4424 are very knowledgeable in their woodworking and metalworking products.