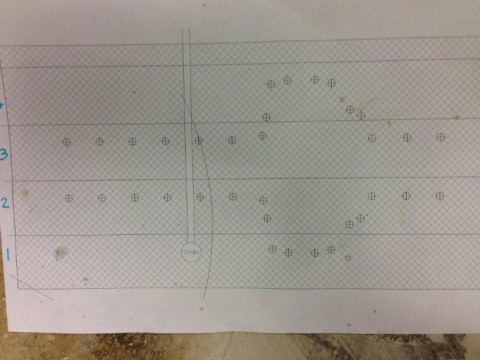

The CopTool Team had the chance to tag along on a job to see a few Diamond Products Core Bore products in action. A friend was drilling 34 6” x 24” holes into some 48 hour old concrete so that some epoxies and anchors specific to the machinery to be installed could be placed. Many times, old anchor bolts have to be drilled out of cured concrete and replaced with newer ones, but in this particular instance the concrete was fresh and there were no old bolts to remove. You can see a picture of the layout of the holes below.

They had two drills going the entire time, working side-by-side to avoid their hoses and cords getting tangled up. Also, they used two drills so they would be able to work together if one of the drills got stuck or some other unforeseen circumstance slowed the work down. In total, three people were working, two people running the drills and removing the cores while one person made a slurry dam and vacuumed up as much of the slurry as they could. The drills were a Core Bore M-2 with a CB748 motor and a Core Bore M-5 with a Weka Dk22 motor. The bits used were Diamond Products PCB 6” x 15” x .187” bits to start the holes with 6” x 26” x .165” to finish. After a short break-in period they were drilling at about 2” per minute, and when it was all said and done it took 10 hours to drill out all 34 holes.

It was critical that the bits were perfectly level for the project to be done right. To accomplish this, they backed the four leveling screws into the base so they were not protruding from the bottom. Then they vacuumed the machine down to the new 28” thick slab and began the leveling process using a magnetic torpedo level on the sides and front of the bit while it was about 1” above the concrete, making sure the bit never touched the concrete while it was being leveled. The leveling screws were adjusted until the bit was level from front to back and side to side.

To remove the cores, first they snapped them off with a screwdriver. They over drilled about 1” into the concrete to make sure the cores would be at least 24” long. Normally they would not over drill quite this much, but there was some worry due to the concrete being so green. After the cores were snapped, they took a ½” carbide bit and drilled into the top of the cores at about at 15 degree angle. Then, all that was left to do was lift straight up and remove the core from the hole.

It was great to get the chance to be on the job and see these great Core Bore products in action. I have to say that I wish I knew more about what kind of machine needed to be mounted into concrete like that. Remember, you can find Core Bore products and bits at Ohio Power Tool, and you can always call a pro with your questions at (800) 242-4424